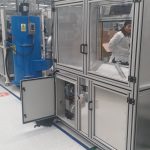

The equipment is developed to test VW Climatronic devices in the assembly line. Through CAN communication, Climatronic EEPROM parameters are read, and they are checked against the final label data and the product configuration file, provided by the manufacturer. If everything is correct, the cabin opens automatically so that the operator leaves the product in its storage box

Multidisciplinary project that involves mechanical, pneumatic, electrical and software design and construction, fully developed in LabVIEW. It integrates industrial digital I / O devices, a National Instruments CAN bus interface, and different peripherals: Keyence code reader, RFID card reader, security curtains, etc

The automatic gate mechanism has been designed in a wear-resistant manner to optimize maintenance interventions.