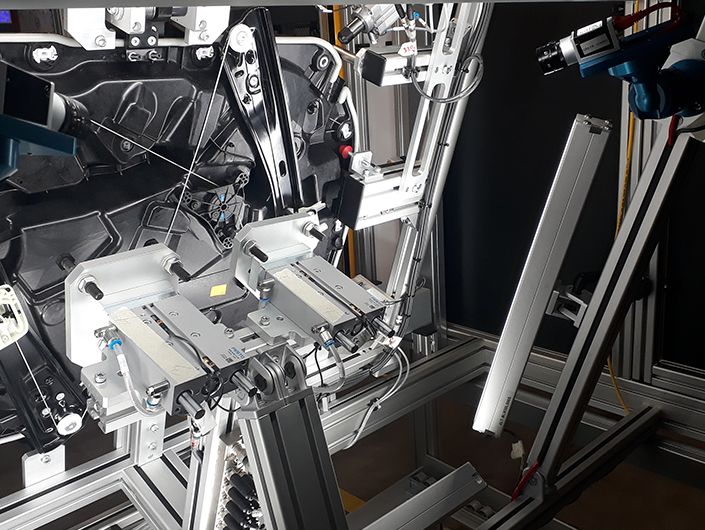

Several similar projects have been carried out, which we include only in this case study. All with the same purpose: to perform an automatic inspection of vehicle door panels using artificial vision.

The inspection consists of detecting the presence / absence of certain elements of the panels, such as bearings, bayonets, etc., and also the correct placement of others, such as skids and traction cables of the window regulator system (window lifters).

The system consists of a National Instrument Industrial Controller (with a Linux Real-Time system that offers robustness and reliability in a very small size), several Gigabit Ethernet area scan cameras and self-developed linear illuminations, which offer an intensity of excellent light and color temperature, in a very robust and easy to install industrial format.