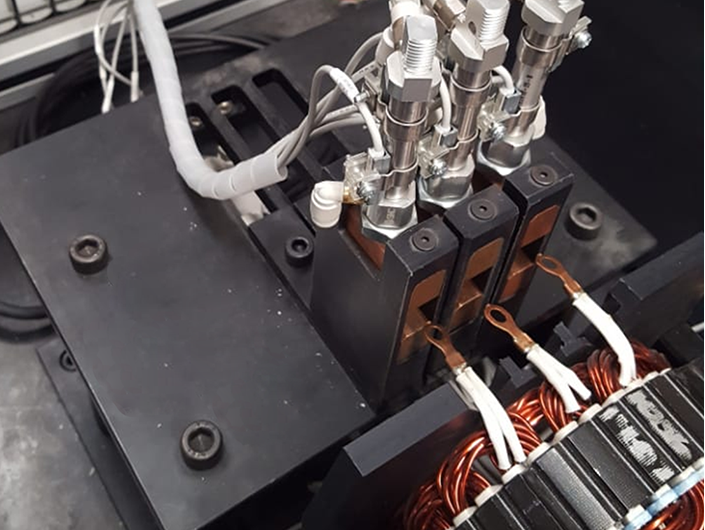

Test bench measuring and testing for the automotive alternator stators coils, with tests up to 1500VAC, the control software of this bank is executed in a National Instruments embedded device called “Compact Rio (cRIO)”, a device with high performance processing capabilities and an ideal tool chain for monitoring and control.

The resistance measurement of each coil was made with the equipment called “Milliohmeter”, the result of the measurement is sent to the cRIO to determine in the software if the measurements are within the ranges suggested by the manufacturer

In the verification of dielectric strength, the “Wayneker” equipment was used, which make tests with very high alternating current voltages with the intention of testing the dielectric strength of the stator coils, this measuring equipment has serial communication which is used to communicate with the cRIO and then analyze the test results in the software. In this way it can be determined if the part under Test will have a correct operation.